Using 3D printing to make implants smart

Back in the 16th century, broken bones were physically manipulated back to the correct orientation by a bone setter. Failing that, the local blacksmith would step in.

Thankfully, advances in medical treatments since the early 1900s have allowed surgeons to use metal implants in healthcare, typically to treat bone diseases including osteoarthritis and inflammatory rheumatoid arthritis, as well as in reconstruction therapy. Though a well-established technology, traditional implants often cause challenges for patients and surgeons. One area currently being developed is that of smart implants, which improve patient outcomes, bringing the technology into the modern age.

“Implants can be smart in two ways, either by being additively manufactured to produce patient specific implants (PSIs) from computed tomography (CT) data, or by incorporating sensors,” explains Matt Parkes, Senior Medical Development Engineer at Renishaw, a company at the forefront of new engineering technologies utilised across sectors in everything from jet engines to dentistry. “Still in the early phases of development, inbuilt sensors could collect patient-specific data, enabling surgeons and other healthcare professionals to tailor treatment to the needs of individual patients.”

What patient challenges can PSIs help overcome? “One of the key issues that traditional implants present is loosening,” explains Parkes. “Particularly common following joint replacement procedures, loosening can be a result of poor osseointegration – the structural and functional connection of the implant with the patient’s bone. This can occur due to wearing over time and is exacerbated by factors including infection and poor compliance with advised physiotherapy regimes.”

Parkes notes this can be exacerbated by the limitations of traditional metal implants, which are only manufactured in a discrete number of shapes and sizes. “It is unlikely patients will receive an implant that fits them accurately,” he concedes. “This can cause poor physical function and contribute to loosening. Poor physical function can also occur because of stress shielding – the process whereby metal implants remove stress from the patient’s bone. The bone responds by reducing in density and therefore becomes weaker.”

Parkes also highlights the increasing incidence of obesity as one of the reasons why joint replacements are becoming more common in young people. “This poses longevity issues as implants can reach their maximum lifespan and need replacing several times during the patient’s lifetime,” he says. “To combat these issues, researchers and engineers have been developing implants in new ways, using techniques such as additive manufacturing (AM). The technology aims to improve the form, fit and function of implants.”

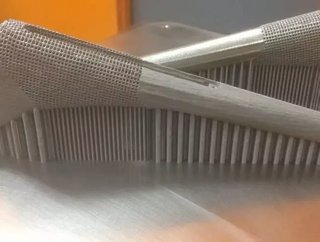

AM, also known as 3D printing, offers exciting opportunities to develop new technologies across industry sectors. It can remove many of the constraints seen in more traditional manufacturing methods such as milling, casting or fabrication. This opens up new possibilities for complex geometries and mass customisation of parts, at a commercially viable cost, that were previously unfeasible. 3D printing is highly suited to the production of medical devices in both cobalt chrome and titanium, and capable of producing complex features and accurate parts.

Renishaw is working to apply additive manufacturing to custom medical device production for craniomaxillofacial implants and guides, and is keen to work with its customers to improve existing custom devices and develop new applications that are yet to be exploited. “Renishaw's laser melting is a pioneering additive manufacturing process capable of producing fully dense metal parts direct from 3D CAD files using a high-powered fibre laser,” explains Parkes. “Parts are built from a range of fine metal powders that are fully melted in a tightly controlled atmosphere layer by layer in thicknesses ranging from 20 to 100 microns.”

AM has been used as a manufacturing method in the medical field for over 10 years, but Parkes believes the technology is yet to reach its full potential in this industry. “Because AM builds an implant layer by layer, it’s possible to produce PSIs that are a more accurate fit for the patient. The manufacturing method also has fewer geometric constraints than subtractive manufacturing. PSIs designed and manufactured according to a patient’s CT scan encourages the implant to integrate with the patient’s bone, reducing the risk of loosening.”

As a result, patients are less likely to suffer pain or require revision surgeries. “As well as being able to manufacture an exact shape, AM enables surgeons to control additional properties of the material,” he adds. “They can design implants that mimic the patient’s bone stiffness, density and trabecular structure, which can reduce stress shielding and improve osseointegration and physical function further.”

Implants can also be made smarter by adding sensors. This allows clinicians to accurately measure patient data – a key to evidence-based medicine, notes Parkes: “One parameter a sensor could measure is temperature, as a raised temperature can indicate an infection before symptoms appear. This could benefit both patients and doctors by enabling treatment before the infection becomes complicated and expensive to treat.”

Parkes believes sensors could also be incorporated into bone reinforcement implants, which are used to help fractures heal. “In this example, sensors can measure the strain exerted on the implant, which indicates the extent the fracture has healed. From this information, surgeons can determine the best time to progress the patient to the next stage of therapy and could also identify healing problems earlier than currently possible,” he argues. “As implant loosening can be affected by non-compliance with physiotherapy, technology has been developed to overcome this issue. Incorporating accelerometers to monitor the movement of patients would allow healthcare professionals to remotely obtain data. These could be used to determine whether a patient is complying with their prescribed physiotherapy and rest regime.”

One institute developing technology in this field is a collaboration between Renishaw and Western University in Ontario, Canada, which has set up the Additive Design in Surgical Solutions (ADEISS) Centre to bring together clinicians and academics to generate novel 3D printed medical devices. “ADEISS recently showcased the smart hip concept, which uses temperature sensors and accelerometers to collect patient data that can be communicated to a remote device,” reveals Parkes. “By making use of advanced sensor technology, there is now potential for the development of implants that can detect an infection and subsequently secrete the appropriate dose of antibiotic to treat it before it becomes symptomatic. This could reduce the number of patients admitted to hospital.”

The ultimate driving force for developing smart implants is the potential to considerably improve patient outcomes. Parkes believes AM offers several benefits, one major advantage being that the fit time schedule is reduced – a benefit to both patients and surgeons.

The benefits smart implants have over traditional metal implants could mean patients would suffer less pain and discomfort and be less likely to become seriously ill due to infection while at lower risk of needing revision surgeries – critical for younger patients. However, Parkes maintains that for widespread clinical adoption of smart implants, there are still challenges to overcome. “Clinicians must run clinical studies to collect data on the safety and performance the implants offer to patients,” he says. “This must all be done in line with regulations such as the EU regulations on medical devices. A further key consideration is the processing of personal data in smart implants and how that data is used by the industry and clinicians.”

The treatment of bone diseases and injuries has come a long way since the days of bone setters and blacksmiths, with patients now able to receive metal implants specifically designed to their individual requirements. Parkes expects that trend to develop further as new technology is enhanced: “Pioneering research institutes are overcoming the hurdles and improving the technology, so the uptake of additively manufactured and data-driven implants is set to rise, improving outcomes for patients and hospitals.”